- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

-

Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine

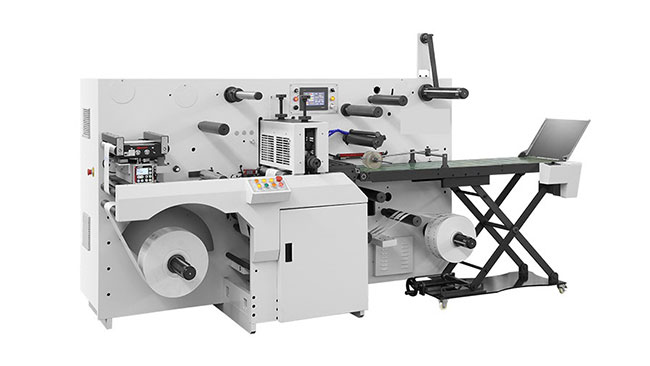

Intermittent Full Rotary Circular Die Cutting Machine

Product Description

Intermittent/full rotary circular die-cutter, an entry-level machine for the in-mold label market, a cost-effective die-cutting solution for IML. This equipment is designed to solve the problems of label printing enterprises such as in-mold labels being unable to be die-cut or the use of traditional equipment being inefficient. This machine integrates the in-mold label full-rotation die-cutting method and the self-adhesive intermittent die-cutting method. The two working modes can be interchanged at will. Small batches of in-mold labels can also be cut in the intermittent mode. It well solves the confusion of printing factory's difficulty in starting the in-mold labeling project. Easily convert from intermittent to full rotation, providing a high quality solution for label materials. In addition, lamination, striping or cutting into sheets are also optional.

Technical parameter

|

Model |

IML-330 |

|

Maximum paper feed width |

330mm |

|

Maximum unwinding diameter |

700mm |

|

Maximum winding diameter |

700mm |

|

Maximum die-cutting speed in all rotations |

110m/min |

|

Intermittent die cutting speed |

60m/min |

|

Self-adhesive die-cutting accuracy |

±0.15mm |

|

In-mold die-cutting accuracy |

±0.25mm |

|

Intermittent maximum die-cutting length |

304.8mm(120T magnetic roller) |

|

Minimum cutting width |

16mm |

|

Die cutting positioning method |

Photocell |

|

Standard die-cut magnetic roller |

120T |

|

Main motor total power |

10kw |

|

Dimensions |

2500x1260x1875mm |

|

Standard die-cut magnetic roller |

120T |

|

Total Weight |

3000KG |

|

Air pressure requirements |

0.4-0.6Mpa |

|

Optional |

Width 420mm/520mm |

|

Unwind |

Discharge waste |

|

Correction |

Single winding |

|

Flat wire mesh |

Discharge waste |

|

Intermittent/Full Rotary Circular Die Cutting |

|

|

Other optional configurations |

|

|

Lamination |

dorsal cut |

|

membrane internal standard |

Winding up and down |

|

Divide |

Circular winding |

|

cut into sheets |

|