If you’ve seen stacks of paper food containers in cafes or takeout shops and wondered how they’re made, the answer lies in a specific piece of equipment. But what is this machine, and what makes it unique to paper food boxes? Let’s clarify it step by step.

What Is a Paper Food Box Making Machine, Fundamentally?

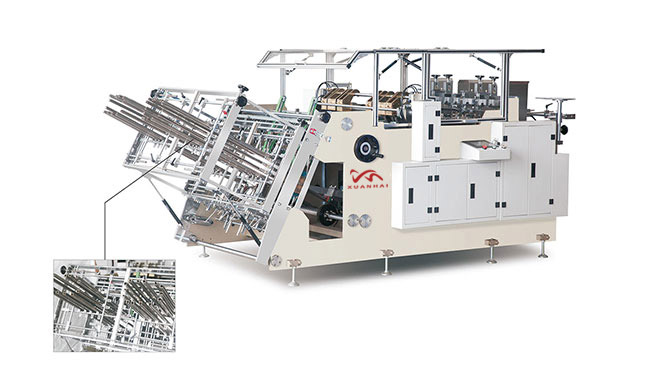

At its most basic, a Paper food box making machine is specialized equipment designed to turn food-grade paper materials into finished, usable paper food boxes. Unlike manual labor or general-purpose paper tools, it’s built to handle the specific needs of food packaging—combining automation and precision to create containers that are safe for food contact, consistent in shape, and ready for immediate use.

It’s not just a “box maker” for paper; it’s a machine tailored to the requirements of food-related packaging, from material compatibility to final form.

What Core Functions Define It?

Every part of the machine’s operation ties back to its purpose of making paper food boxes. Here are its key functions:

1. Handling Food-Grade Raw Materials

The machine starts by accepting paper materials that meet food safety standards—such as grease-resistant kraft paper or coated paperboard. It’s designed to feed these materials smoothly without damaging their food-safe properties.

2. Precision Cutting and Creasing

To form a box, the paper needs exact cuts (for size) and creases (for folding). The machine uses sharp, calibrated tools to cut the paper into flat “blanks” (the unfolded box shape) and create clean creases where folds will go—ensuring each blank can be formed into a uniform box.

3. Automated Forming

After cutting and creasing, the machine folds the paper blank along the creases and secures the edges (usually with food-safe adhesive or mechanical tucking). This step turns the flat blank into a 3D, closed box that can hold food.

4. Quality-Checked Ejection

Finally, the machine ejects finished boxes that meet consistency standards—no misshapen edges or weak seals. The boxes are ready to be stacked and used for food packaging.

What Key Traits Make It a "Paper Food Box Making Machine"?

Not all paper box machines qualify as paper food box making machines. Two traits define it:

1. Food Safety Compatibility

All parts of the machine that touch the paper are made from materials that won’t contaminate food (e.g., food-grade stainless steel). It also avoids using chemicals or lubricants that could seep into the paper—critical for meeting food packaging regulations.

2. Adaptability to Food Box Needs

Food boxes come in various sizes (from snack cups to large takeout containers) and styles (with lids, compartments, or fold-flat designs). These machine can adjust its cutting, creasing, and forming settings to match these diverse food-focused designs.

Wrapping Up

In short, a Paper food box making machine is specialized, food-safe equipment that automates the process of turning food-grade paper into consistent, usable paper food containers. Its entire design and function revolve around the unique needs of food packaging—safety, precision, and adaptability.

If you want to learn more about how such equipment can support your food packaging workflow, our product page details options suited for different box types and production needs.

- Paper Food Box Making Machine

- Three-dimensional carton forming machine

- Multi grid paper lunch box forming machine

- Hamburger box making machine

- Food box making machine

- Right angle paper box making machine

- Carton Erecting Machine

- Paper cup making machine

- Paper stick making machine

- Sticker Label Making Machine

- Sticker Label printing machine

- Die cutting machine

- Label Slitting and rewinding machine

- Label Making Auxiliary equipment

- Printing Quality Checking Machine

- Plastic Container Making Machine

- Plastic cup making machine

- Plastic cup printing machine

- Plastic lid printing machine

- PVC Shrink Sleeve Making Machine

- PVC Shrink sleeve gluing machine

- PVC Shrink sleeve cutting machine

- PVC film slitting machine

- PVC film printing machine

- Disposable Products Making Machine

- Plastic glove making machine

- Medical Disposable Making Machine

- Hotel Amenities Making Machine

- Paper confetti die cutting machine

- Party products making machine